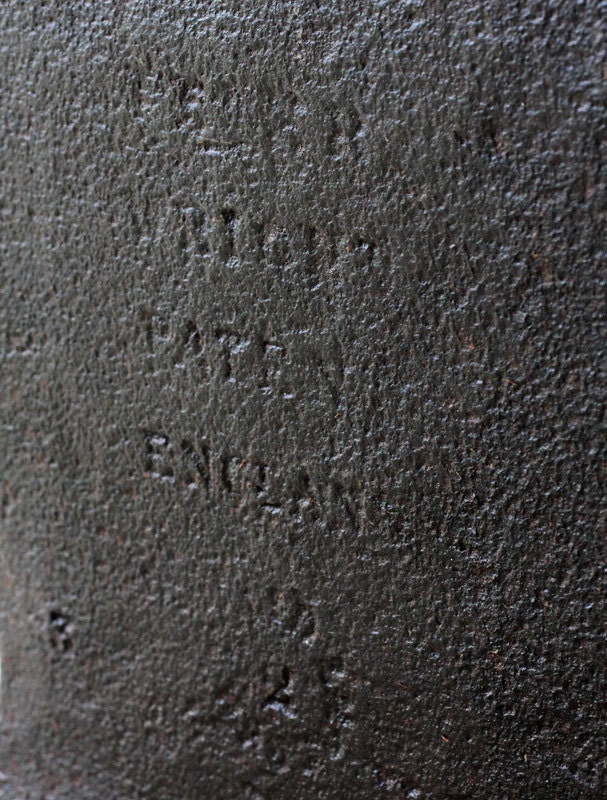

If you have any questions on this please contact me and I can go over the details and the specifics on the anvil you are buying. There are a small percentage of my latest shipment of 260# Classic anvils that will require some casting clean up. The three are added together for the total weight. The next figure is quarter hundred weights which equal 28 pounds and the last number is whole pounds. The vast majority of the anvils require very little work. The first figure to the left is hundred weights which equal 112 pounds. One of the reasons the anvils I sell are such a high quality value is that I leave it to the customer to dress the anvil (radius the edges, chamfer the hardy hole if desired and do a small amount of cleanup that is associated with a casting of any kind). He gave it to me for helping pioneer a road into the woods where Katrina carried his shrimp boat out of his yard and off its trailer. You will have some clean up work to do in order to make the hardy hole one uniform size in some of the 260# anvils in my latest batch, to meet off the shelf tooling requirements. I got from a guy in Slidell Louisiana in 2005 that went by Crazy Cajun Dave. I own an ames1 and can attest to the accuracy and precision of this tester. Anvils similarly need some dressing as well. I believe The tester that you posted is Chinese knock off of an ames model 1. Usually a new hammer has to have the edges radiused and the peen needs to be ground to blunt the sharp edges on it. This is similar to dressing a new hammer. Most new anvils require some degree of dressing and clean up by the first owner of the anvil. Those of us who have only experienced used anvils, assume that a good, clean used anvil arrived in it's present condition when first delivered to the first owner. Peter Wrights are very popular anvils today and sell for a premium, must have been popular when made too judging from how many old ones I see, with out the doubt the most common English anvil.I used to work on a Peter wright and personally I thought it was very noisy and I think their faces are kind of soft, many that you see have a sway back. To put this in perspective, most new anvils require some degree of dressing by the first owner. If buy off the shelf steel and weld you hardy tools, this will impact you. If you forge your hardy tools from old truck or car axles this should not have any impact on your tooling. Low rebound indicates that there is a lot of force being lost to other forces such as absorption by the material, the anvil base, and the surface the anvil base rests on. These are cast steel anvils and there is some degree of variation in the 260 lb Classic anvil's hardy size. The higher the rebound, the more force the anvil is returning to the hammer (or hot metal in the case of forging). Dimensions of hardy holes in some of the 260 # anvils may vary by up to 1/8".

0 kommentar(er)

0 kommentar(er)